In the mining industry, maximizing productivity while ensuring safety and efficiency is always a primary concern. As mining operations evolve, the importance of advanced technologies and systems that can enhance performance becomes more significant. One of the essential innovations in the industry today is Longwall Electrical Systems, which have proven to revolutionize the way underground mining operations are conducted. These systems provide a host of benefits that allow mining companies to maximize productivity while minimizing downtime and operational costs.

What are Longwall Electrical Systems?

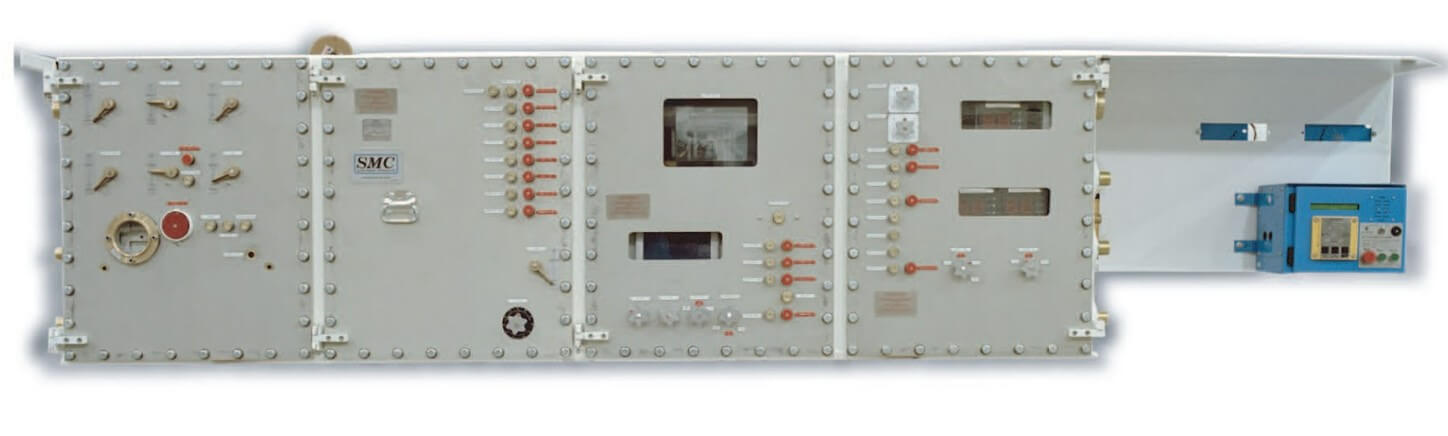

Longwall mining is a method of underground coal mining where a large panel of coal is mined in a single slice, often hundreds of meters long, and the method relies heavily on advanced electrical systems. Longwall Electrical Systems are designed to support the operation of these mining systems, including the equipment that drives the longwall shearers, conveyors, and other critical machinery.

These systems play a crucial role in ensuring that the equipment runs efficiently, helping operators control the machinery and improve overall mining output. The integration of robust electrical systems is essential for automation and safety, ensuring that mining operations remain smooth and productive over extended periods.

How Longwall Electrical Systems Boost Productivity

- Enhanced Automation for Greater Efficiency

One of the primary ways that Longwall Electrical Systems helps maximize productivity is through automation. The ability to control mining equipment remotely, adjust settings in real-time, and monitor performance with precision is a significant advantage. Longwall shearers, for example, can be operated more efficiently, extracting coal from vast seams without the need for constant manual oversight. Automation improves the accuracy of the mining process, reducing errors and ensuring a steady flow of coal extraction.

Automation also improves the consistency of the mining process, reducing the chances of human error that can lead to delays or inefficient operations. This streamlined approach to mining allows operators to focus on optimizing the system as a whole rather than managing individual tasks. Automation and remote monitoring also help reduce the physical strain on workers, allowing them to focus on other high-priority tasks.

- Reduced Downtime with Predictive Maintenance

Predictive maintenance is another key feature that enhances productivity in longwall mining operations. Longwall Electrical Systems are equipped with sensors and data analytics tools that can detect the early signs of potential equipment failure. By continuously monitoring the condition of the system, operators can identify issues before they lead to breakdowns.

With predictive maintenance, companies can schedule repairs during planned downtimes, rather than reacting to unforeseen failures that may require emergency shutdowns. This predictive approach reduces the amount of unplanned downtime, which can significantly boost productivity. The system's ability to forecast when a part might fail ensures that replacement parts are available and that service crews can perform necessary work without interrupting operations.

- Improved Energy Efficiency

Energy costs are a significant portion of the overall cost structure in any mining operation. Longwall Electrical Systems are designed with energy efficiency in mind. These systems optimize power distribution, ensuring that energy is used where it is needed most and preventing energy waste in other areas. Modern electrical systems can automatically adjust the power settings based on the mining conditions and equipment needs, making operations more energy-efficient.

In addition to improving energy consumption, longwall systems are also designed to reduce the wear and tear on electrical components, which means fewer breakdowns and less frequent maintenance. This further contributes to a reduction in operational costs and an increase in overall productivity.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

- Safety Enhancements Lead to Fewer Disruptions

Safety is paramount in underground mining. The integration of Longwall Electrical Systems has significantly enhanced the safety of mining operations, reducing accidents and improving working conditions for employees. With advanced safety features, such as automatic shutdowns in case of malfunctions, and continuous monitoring of air quality and structural integrity, these systems ensure that potential risks are mitigated before they can escalate into dangerous situations.

Moreover, these systems help provide real-time data to operators, enabling them to assess the status of the operation and make informed decisions quickly. In the event of an emergency, operators can take corrective action immediately, minimizing the risk of injury or equipment damage. The ability to monitor and manage mining operations remotely also ensures that personnel are not put in harm's way unnecessarily, helping to reduce disruptions to operations caused by safety incidents.

- Streamlined Communication for Improved Coordination

Effective communication between team members is critical in any mining operation, especially in a longwall mining setup, where numerous tasks and machines are operating simultaneously. Longwall Electrical Systems incorporate advanced communication systems that allow for seamless coordination among team members and between machinery.

Real-time communication systems ensure that operators receive up-to-the-minute information on equipment performance, operational conditions, and safety data. This constant flow of information allows for quicker decision-making and ensures that the entire operation runs smoothly. When operators are equipped with the latest data and technology, they are better positioned to adapt to changing conditions in the mine, reducing delays and improving productivity.

- Scalability and Flexibility

As mining operations grow and evolve, so too must the systems that support them. Longwall Electrical Systems offers scalability and flexibility, allowing operations to expand without the need for a complete overhaul of the existing infrastructure. These systems can be adapted to different mining environments, such as those with varying depths, mineral compositions, or ore quality.

This adaptability makes it easier for mining companies to scale their operations based on changing market demands or technological advancements. Whether they are upgrading equipment, integrating new automation tools, or expanding mining panels, the flexibility of the longwall electrical systems allows operators to adjust without significant downtime or lost productivity.

- Data-Driven Decision-Making for Continuous Improvement

One of the biggest advantages of Longwall Electrical Systems is their ability to collect and analyze vast amounts of data in real-time. Data on everything from equipment performance to environmental conditions is continuously gathered and processed, providing operators with critical insights into their operations.

By analyzing this data, mining companies can identify areas for improvement and make data-driven decisions that enhance efficiency. Whether it's fine-tuning equipment settings, adjusting mining schedules, or optimizing resource allocation, data analytics plays a crucial role in ensuring that productivity is continually maximized.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Longwall Electrical Systems and Environmental Impact

While Longwall Electrical Systems offer numerous productivity benefits, they also contribute to reducing the environmental impact of mining operations. By improving energy efficiency and reducing waste, these systems help minimize the carbon footprint of mining operations. Additionally, more efficient coal extraction means less disruption to the surrounding environment, as the mining process becomes more precise and controlled.

In an era where sustainability is a top priority for many industries, including mining, Longwall Electrical Systems represents a step forward in balancing productivity with environmental responsibility.

Conclusion

In today's competitive mining industry, Longwall Electrical Systems have become an integral part of maximizing productivity. These systems help streamline operations, reduce downtime, enhance safety, and ensure that energy is used efficiently. By adopting longwall electrical technology, mining companies can ensure that they remain competitive while improving their environmental footprint and ensuring worker safety.

From automation and predictive maintenance to data-driven decision-making and energy optimization, these systems are revolutionizing the mining industry and helping operators unlock new levels of efficiency and profitability. As mining operations continue to evolve, the role of Longwall Electrical Systems will undoubtedly become even more critical in achieving higher productivity and operational excellence.

Products We Offer:

- Explosion Proof Equipment

- Transformers

- Arc Guard

- Longwall Electrical Systems

- Capacitor Trip Devices

- Electrical Equipments like capacitor banks, switch houses, junctions, and splice boxes.

Power up your productivity with Becker Mining's ground fault relays - the reliable and efficient solution for all your power distribution needs. Call us today!