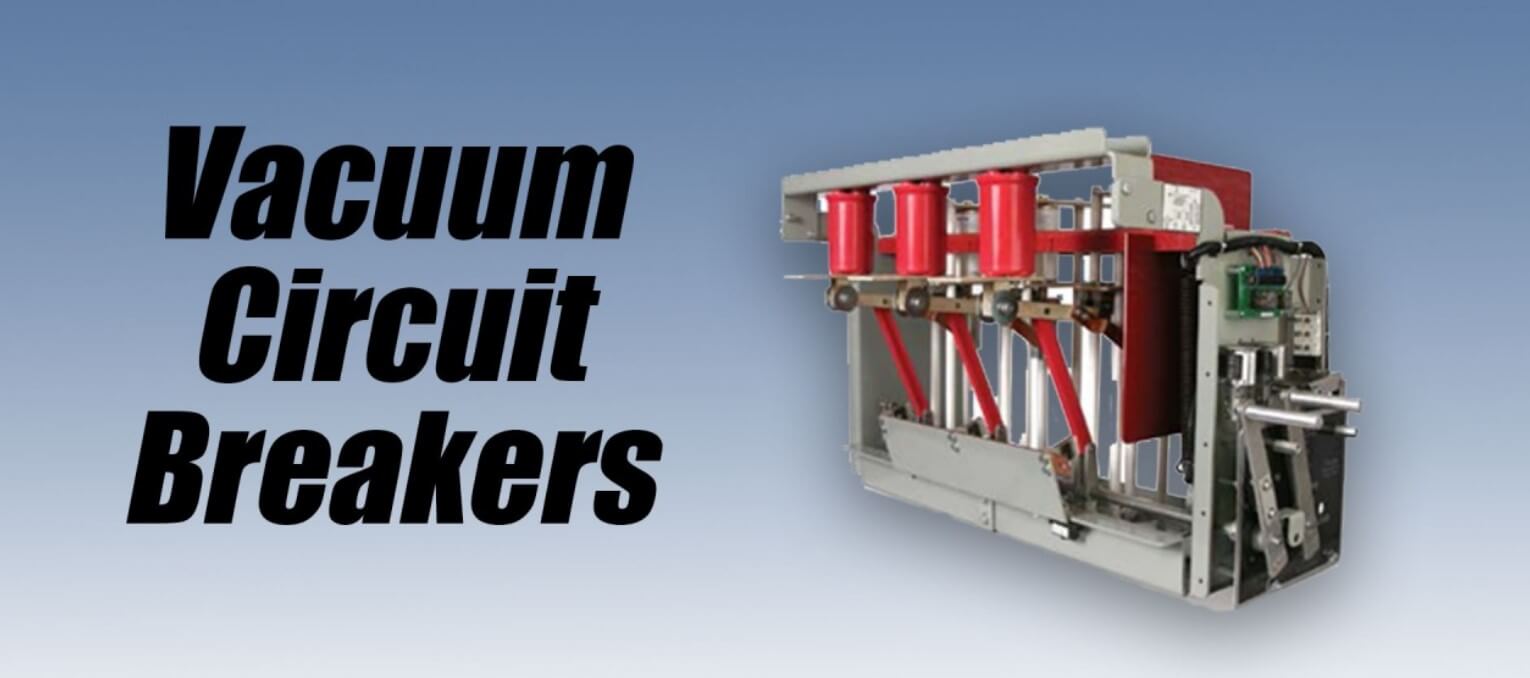

Vacuum circuit breakers are devices that prevent unintended currents from electrical systems caused by short circuits. The vacuum circuit breaker works by interrupting the current when a fault is detected, preventing damage to the electrical system. The vacuum interrupter was introduced in 1960 and has since seen significant improvements due to advances in engineering.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

The ionization of metal vapor in the contacts causes an arc to be generated after the contacts are opened. This arc is quickly extinguished as the electrons, metallic vapors, and ions produced by the arc condense on the contacts of the circuit breakers, restoring the dielectric strength. Vacuum circuit breakers are more efficient because of their ability to quickly recover dielectric strength.

Vacuum circuit breakers are also less expensive to maintain, as they do not require replacement as frequently as other types. These systems are perfect for medium voltage applications, where safety and reliability must remain high over a long period without the need for replacement or maintenance.

The arc is created by the ionization of metal ions. Its characteristics are highly dependent on the materials of the contacts.

It works differently from other circuit breakers in terms of arc interruption. The vapor is released when the contacts separate and fill the contact area. The vapor is made up of positive ions that are liberated from the contacts. Its density depends on the amount of current. After reaching zero current, the dielectric strength of the vapor is restored if its density is reduced.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Working Principle

In vacuum circuit breakers, multiple parallel arcs are formed for small currents, dividing the total current into many paths which repel each other and spread over contact surfaces. The diffused arc is a process that can be interrupted quickly due to its nature. These vacuum circuit breakers are also more resistant to thermal stress caused by overloads and require less maintenance for optimal performance because no arcing or other sputtering materials accumulate on the contacts.

The chopping of current in vacuum circuit breakers is largely dependent on the vapor pressure and the properties of the electron emission of the contact material. The chopping is also affected by the thermal resistance of the material. The lower the thermal resistivity, the higher the chopping. By selecting a material that has a large amount of metal vapor, the current can be reduced to a low value. It should only be used with caution as it can affect the dielectric power.

Vacuum circuit breakers have a long life expectancy and are more reliable than other circuit breakers. They also require less maintenance due to the fact that they don't need to be repaired or cleaned as often. They can also reduce the arc interruption time by their rapid improvement in dielectric strength. This makes them perfect for medium voltage applications, where safety is a priority, and reliability must be maintained over long periods without the need for replacement or additional maintenance.

Conclusion

Vacuum circuit breakers stand as crucial components in electrical systems, effectively preventing damage caused by short circuits through their efficient interruption of current. With their inception in 1960 and continuous advancements in engineering, these breakers have proven their reliability and efficacy. Their ability to quickly recover dielectric strength, reduced maintenance requirements, and cost-effectiveness make them ideal for medium voltage applications where long-term safety and reliability are paramount.

The unique working principle of vacuum circuit breakers, involving the generation and rapid extinction of arcs, sets them apart from their traditional counterparts. The controlled release of metal vapor and its impact on dielectric strength contribute to their superior performance. Moreover, their resistance to thermal stress and the minimal accumulation of sputtering materials enhance their durability and reduce maintenance needs.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Contact us Today

Consider vacuum circuit breakers by Becker Mining if you are in the mining industry and want to protect electrical equipment that is reliable and safe. These breakers are of high quality and offer durability as well as superior performance. They will protect your equipment from dangerous electrical faults.

Becker Mining offers a variety of vacuum circuit breakers to suit the needs of the mining sector. Contact our team today to learn more about how vacuum circuit breakers will help you keep your mining operation running smoothly and safely.

Products We Offer:

- Explosion Proof Equipment

- Transformers

- Arc Guard

- Longwall Electrical Systems

- Capacitor Trip Devices

- Electrical Equipments like capacitor banks, switch houses, junctions, and splice boxes.

Power up your productivity with Becker Mining's ground fault relays - the reliable and efficient solution for all your power distribution needs. Call us today!

GET IN TOUCH

In a hurry? Call us at 276-285-3841