Surface mining is a prevalent method of extracting valuable minerals and resources from the Earth's surface. Unlike underground mining, where tunnels and shafts are used, surface mining involves the removal of soil and rock that covers mineral deposits. This technique is employed for various minerals, including coal, copper, iron ore, and gold. As the demand for these resources continues to grow, so does the importance of efficiency, safety, and sustainability in mining operations. Electrical equipment plays a crucial role in achieving these goals, making it indispensable in surface mining operations.

Understanding Surface Mining

Surface mining is the most common method for mining ores and minerals that are located close to the Earth's surface. The process begins with the removal of overburden, which is the layer of soil and rock covering the mineral deposit. This is typically followed by the extraction of the mineral itself. The methods of surface mining include open-pit mining, strip mining, quarrying, and mountaintop removal.

- Open-pit mining involves digging a large pit in the ground to access the ore.

- Strip mining involves removing long strips of overburden to access the minerals beneath.

- Quarrying is used for extracting building materials like stone and gravel.

- Mountaintop removal involves removing the summit or summit ridge of a mountain to access coal seams underneath.

Each of these methods requires a significant amount of equipment and technology to be executed efficiently and safely. Electrical equipment, in particular, is critical for powering machinery, ensuring safety, and improving the overall efficiency of the mining process.

The Role of Electrical Equipment in Surface Mining

Electrical equipment is essential in surface mining operations for several reasons. It powers the machinery, ensures safety, and contributes to environmental sustainability. Here are some of the key roles that electrical equipment plays in surface mining:

1. Powering Mining Equipment

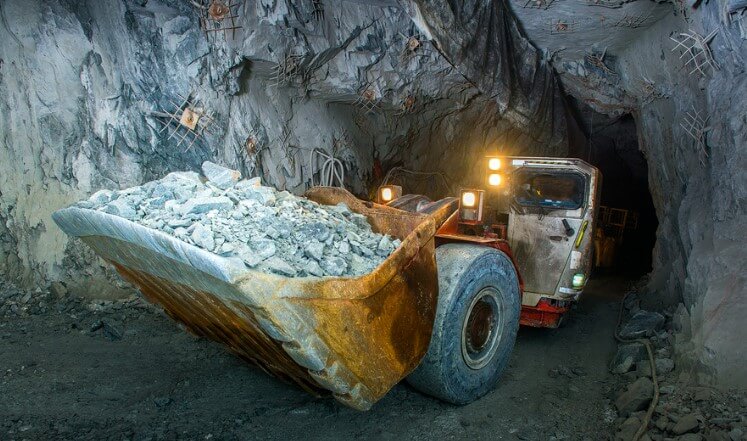

Surface mining operations rely on heavy machinery to extract and transport minerals. These machines, including draglines, shovels, and haul trucks, require a substantial amount of power to operate. Electrical equipment, such as motors and generators, provides the necessary power to run these machines efficiently.

Electric Shovels: Electric shovels are used to excavate large quantities of overburden and ore. These machines are powered by high-voltage electrical systems, which allow them to operate continuously without the need for frequent refueling, as would be the case with diesel-powered machinery.

Draglines: Draglines are massive machines used to remove overburden in strip mining operations. They are also electrically powered and can move large volumes of material in a single pass, making them highly efficient.

Haul Trucks: In surface mining, haul trucks transport extracted materials from the mine site to processing facilities. Electric drive systems in haul trucks provide several advantages over mechanical drive systems, including improved fuel efficiency, lower maintenance costs, and reduced greenhouse gas emissions.

The use of electrical equipment in powering mining machinery is not only more efficient but also contributes to reducing the overall carbon footprint of surface mining operations.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

2. Ensuring Safety in Mining Operations

Safety is a top priority in surface mining, where workers are exposed to various hazards, including heavy machinery, high voltages, and explosive materials. Electrical equipment plays a critical role in ensuring the safety of workers and preventing accidents.

Electrical Protection Systems: Electrical protection systems are designed to prevent electrical faults, such as short circuits and overloads, which can lead to fires or equipment damage. These systems include circuit breakers, fuses, and protective relays that automatically disconnect power in the event of a fault, reducing the risk of accidents.

Grounding and Bonding: Proper grounding and bonding of electrical equipment are essential for preventing electrical shocks and fires. Grounding ensures that any stray electrical currents are safely discharged into the ground, while bonding connects all metal parts of the equipment to ensure they are at the same electrical potential.

Explosion-Proof Equipment: In surface mining, there is a risk of explosions due to the presence of flammable gases and dust. Explosion-proof electrical equipment is designed to operate safely in these hazardous environments. This equipment is constructed to contain any sparks or flames within the device, preventing them from igniting the surrounding atmosphere.

Emergency Shutdown Systems: In case of an emergency, such as a fire or equipment malfunction, emergency shutdown systems are essential for quickly disconnecting power and stopping machinery. These systems are often integrated with other safety systems, such as fire suppression and gas detection, to provide comprehensive protection.

The integration of advanced electrical equipment in safety systems helps to minimize risks and protect workers, making surface mining operations safer.

3. Enhancing Efficiency and Productivity

Efficiency is a key factor in the profitability of surface mining operations. Electrical equipment contributes to improving efficiency by automating processes, reducing downtime, and optimizing energy consumption.

Automation and Remote Control: Many surface mining operations are now using automation and remote control technologies to enhance productivity. Electrical equipment, such as programmable logic controllers (PLCs) and remote-control systems, allows operators to control machinery from a distance, reducing the need for manual intervention and improving safety.

Variable Frequency Drives (VFDs): VFDs are used to control the speed of electric motors, allowing for precise control of machinery and reducing energy consumption. In surface mining, VFDs are commonly used in conveyors, pumps, and ventilation systems, where they help to optimize performance and reduce operating costs.

Condition Monitoring Systems: Electrical equipment is also used for condition monitoring, which involves continuously monitoring the performance of machinery to detect any signs of wear or failure. This allows for predictive maintenance, where equipment is serviced before it fails, reducing downtime and improving efficiency.

Energy Management Systems: Surface mining operations consume a significant amount of energy. Electrical equipment, such as energy management systems, helps to optimize energy usage by monitoring consumption and identifying areas where energy can be saved. This not only reduces operating costs but also contributes to environmental sustainability.

By leveraging electrical equipment to enhance efficiency and productivity, surface mining operations can achieve higher output with lower costs, improving their overall profitability.

4. Supporting Environmental Sustainability

Environmental sustainability is becoming increasingly important in the mining industry, as companies seek to minimize their impact on the environment and comply with regulations. Electrical equipment plays a vital role in supporting sustainability initiatives in surface mining.

Electric-Powered Machinery: One of the most significant contributions of electrical equipment to sustainability is the use of electric-powered machinery. Electric shovels, draglines, and haul trucks produce fewer emissions compared to their diesel-powered counterparts. This helps to reduce the carbon footprint of surface mining operations.

Renewable Energy Integration: Some surface mining operations are now integrating renewable energy sources, such as solar and wind, into their power supply. Electrical equipment, such as inverters and transformers, is essential for converting and distributing this renewable energy to power mining machinery.

Dust Control Systems: Surface mining operations can generate a significant amount of dust, which can have adverse effects on the environment and nearby communities. Electrical equipment is used in dust control systems, such as water sprays and electrostatic precipitators, to reduce the amount of dust generated during mining activities.

Water Management Systems: Water is a critical resource in surface mining, used for processes such as dust suppression and ore processing. Electrical equipment, such as pumps and control systems, is used to manage water usage efficiently, reducing waste and minimizing the impact on local water resources.

Rehabilitation and Reclamation: After mining operations are completed, the land must be rehabilitated and returned to its natural state. Electrical equipment, such as seeders and irrigation systems, is used in the rehabilitation process to restore vegetation and support the ecosystem.

By incorporating electrical equipment into sustainability initiatives, surface mining operations can reduce their environmental impact and contribute to the preservation of natural resources.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

Innovations in Electrical Equipment for Surface Mining

The mining industry is continuously evolving, with new technologies and innovations being developed to improve efficiency, safety, and sustainability. In recent years, there have been several advancements in electrical equipment that are transforming surface mining operations.

1. Battery-Powered Equipment

One of the most significant innovations in surface mining is the development of battery-powered equipment. Traditional mining machinery, such as haul trucks and loaders, is typically powered by diesel engines, which produce significant emissions. Battery-powered equipment offers a cleaner alternative, reducing greenhouse gas emissions and improving air quality at mine sites.

Battery technology has advanced rapidly in recent years, with modern batteries offering longer runtimes and faster charging times. This makes battery-powered equipment a viable option for surface mining operations, where the demand for low-emission solutions is growing.

2. Smart Grid Technology

Smart grid technology is another innovation that is transforming surface mining operations. A smart grid is an electrical grid that uses digital communication technology to monitor and manage the production, distribution, and consumption of electricity. In surface mining, smart grid technology can be used to optimize energy usage, reduce costs, and improve the reliability of power supply.

For example, smart grid technology can be used to manage the integration of renewable energy sources, such as solar and wind, into the power supply for mining operations. It can also be used to monitor the performance of electrical equipment in real time, allowing for predictive maintenance and reducing the risk of equipment failure.

3. Advanced Automation and AI

Automation and artificial intelligence (AI) are playing an increasingly important role in surface mining operations. Advanced automation systems use electrical equipment, such as sensors and controllers, to monitor and control machinery with minimal human intervention. AI algorithms can analyze data from these systems to optimize performance and predict maintenance needs.

For example, AI can be used to analyze data from haul trucks to optimize their routes and reduce fuel consumption. It can also be used to monitor the performance of electric shovels and draglines, identifying any signs of wear or failure before they lead to costly downtime.

Conclusion

The importance of electrical equipment in surface mining cannot be overstated. From powering machinery to ensuring safety, enhancing efficiency, and supporting environmental sustainability, electrical equipment plays a crucial role in the success of surface mining operations. As the mining industry continues to evolve, innovations in electrical equipment, such as battery-powered machinery, smart grid technology, and advanced automation, are shaping the future of surface mining.

For mining companies, investing in modern electrical equipment is not only a matter of improving operational efficiency but also a commitment to safety, sustainability, and environmental responsibility. By leveraging the latest advancements in electrical technology, surface mining operations can achieve greater productivity, reduce their environmental impact, and contribute to the sustainable development of the industry.

At Becker Mining USA, we are dedicated to providing cutting-edge electrical equipment and solutions for the surface mining industry. Our commitment to innovation and excellence ensures that our clients have access to the most advanced technology and support, helping them to succeed in a competitive and ever-changing industry.

Our Expert Services

Swartz Engineering provides top-quality products to meet our customers' needs. We also make sure our products work reliably and safely. Our products include:

- Type 76 DC Relay

- Type 82 DC Relay

- Swartz Engineering’s Type 64 Ground Relay

- Type 32 Reverse Current Relay

- Type 150 DC

- CSM Shield Monitor

- Metal Oxide Surge Arrestors

- Transducers

- MVIS SL Slim-line Contactor

- Fully-tested Power Control Rooms

- Swartz Engineering’s Portable Substations

CONTACT US

Take the first step towards powering up your operations! call us at 276-285-3841