With the movement from diesel-powered to more electric mining equipment and tools in today’s mining world, the importance of electricity on a mine site has never been more vital. From the drilling process to hauling, to the processing of everything mined, electrical power runs it all.

In this list, we will take a look at a couple of different electrical system types that can be used in an array of mining sites and projects from surface to deep underground mines.

Mining Power Centers

Mining power centers, also known as Load Centers. They convert a large amount of electricity to a lower voltage output. These centers are durable and reliable, meeting all mine-use safety requirements. They can handle inputs of 5 to 25 kilovolts, and deliver an output between 480-1,000 volts. They also usually come with protections from overcurrent, inducing metering, monitoring information, as well as a direct disconnect plug for safety.

Benefits

- Increased Efficiency: Mining power centers can provide power to multiple pieces of electric mining equipment simultaneously, reducing downtime and increasing efficiency.

- Reduced Operating Costs: By using a mining power center, miners can reduce operating costs associated with maintaining and servicing multiple pieces of equipment. Instead, power is consolidated and delivered through a single center.

- Improved Safety: Mining power centers protect miners and equipment from electrical hazards. With advanced safety features, such as ground fault protection, arc flash protection, and thermal overload protection.

- Environmentally Friendly: Mining power centers are designed to be energy-efficient, reducing the fuel required to power mining equipment.

What is Electric Mining Equipment?

Electric mining equipment refers to machinery and vehicles powered by electricity instead of traditional fossil fuels such as diesel. These electrically-driven machines utilize advanced technologies, including electric motors, portable substations, and power electronics, to perform various mining tasks, from excavation and transportation to processing and ventilation.

Future Prospects

The future of electric mining equipment looks promising. As technological advancements continue, we can expect further improvements in battery capacity, power electronics, and charging infrastructure. These developments will lead to extended operational hours, increased machine autonomy, and reduced charging times.

Additionally, the integration of automation and artificial intelligence in electric mining equipment will enhance safety, efficiency, and productivity. Intelligent systems can optimize energy usage, monitor machine health, and enable predictive maintenance, leading to enhanced overall performance and cost savings.

Motor Control Centers

Most often, motor control centers use energy for mines with a lot of high-powered equipment such as conveyors, pumps, and fans. These control centers tend to come with soft-start systems, PLC-controlled variable frequency drives, as well as across-the-line arrangements.

Switchgear

We design switchgear with the purpose of protecting mines that have a lot of high-voltage systems working within them. These high-voltage circuit systems come with a much higher risk of electrocution no matter the type of mine - surface, substation, or underground. Switchgears are able to isolate potentially dangerous systems and protect them, keeping everyone safe and allowing your mine to still have the power it needs.

Benefits

- Enhanced safety: Switchgear helps protect electrical equipment from electrical faults and overloads, which can cause fires, explosions, and other safety hazards.

- Improved reliability: Switchgear can isolate faults in electrical systems, preventing them from affecting other parts of the system and minimizing downtime and repair costs.

- Efficient maintenance: Switchgear allows for easier maintenance and repair of electric mining equipment, reducing downtime and costs associated with equipment failure.

- Increased flexibility: Switchgear enables the configuration of different electrical systems and the integration of renewable energy sources, allowing for more significant power generation and distribution flexibility.

- Cost savings: Switchgear can help reduce energy waste and improve energy efficiency, leading to cost savings for businesses and individuals.

Power Protection in All Aspects

Becker Mining switchgear is a reliable source of electrical energy distribution. It is the result of a decades-long experience in design, manufacturing, and marketing. All switchgear has a rugged construction to ensure strength and durability.

Becker Mining has a wide range of metal-clad switchgear designs, including:

- Voltages: 5kV - 38kV

- Interrupter switchgear with metal enclosure

- Switchgear with a dual rating

- Automatic transfer switchgear

Custom-Built for Optimal Performance

Becker Mining switchgear allows for future expansion and can work with any manufacturer’s circuit breaker. It features removable end walls and double-walled construction between the switchgear compartments. This adds safety and durability to electric mining equipment. The fluidized epoxy bus insulation has superior thermal and dielectric characteristics. A fully coated base assembly prevents corrosion and guarantees long life.

Other benefits and features include:

- Before shipment, the device was fully wired and tested.

- Externally removable air filter boxes that can be removed with back-to-back louvers.

- Testing and lab capabilities in-house

Longwall Controls

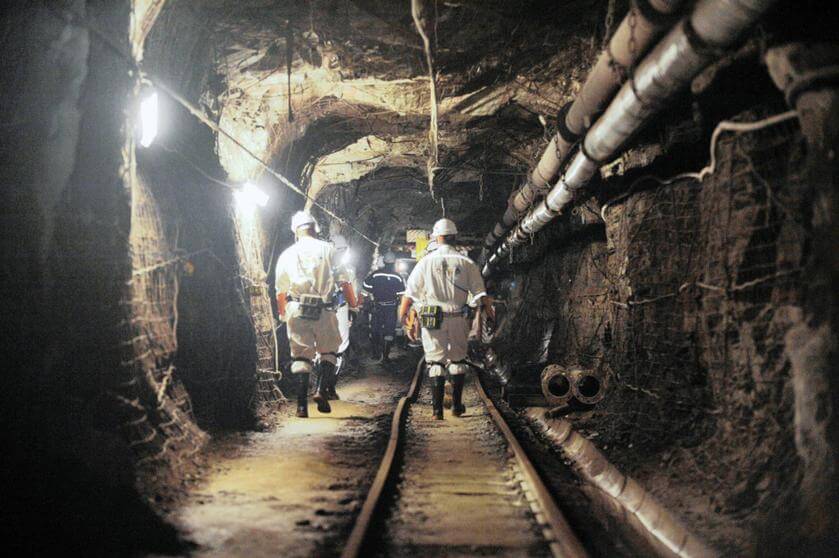

A perfect option for projects involving mining minerals from deep, underground project sites, Longwall controls help run large machines with lots of horsepower and complicated arrangements. This system is perfect for deep projects because we normally house them in explosion-proof cases.

Becker Mining can adapt its longwall monitoring and communications system to suit any customer's needs. We design our system to fit your longwall and provide better solutions for your layout and environment.

Internationally accredited, our emergency stop system has a safety rating of SIL3. Depending on the situation, customers can set them to SIL (Safety Integrity Level) 2, 3, or 4. It is the most reliable and safest emergency stop system available. This unique transmission method allows the simultaneous transmission of high-integrity SIL3 short wall emergency stop signals and monitoring and control signals to gas monitoring.

Flexible and Unique System

- Our unique transmission system allows digital and analog signals to be transmitted over a 2-wire cable. It can accept digital and analog inputs (e.g. Full switch monitoring, gas monitoring, and temperature monitoring on the longwall all-on-one cable

- A new speech message transmission can send up to 255 prerecorded voice messages

- Communicates fault status information of outbye or longwall conveyors in precise speech

- Monitors of digital and analog signals allow for complete monitoring of all conveyor devices. This allows for quick updates. Rapid diagnosis of the cause of belt stoppage will minimize downtime. Each switch must be monitored.

- Interface to all PLC/DCS systems

- There can be up to 128 digital and analog signals per conveyor.

- The transmission system is equipped with a high CMRR (common mode rejection ratio), which ensures noise immunity and prevents noise from being induced.

- Long-distance transmission over 10km.

- Only long-distance transmission system that has SIL3 safety rating

Substations

Substations are there to help transform utility-supplied electricity into the voltage required to run operations within your underground or surface mine. These systems come in portable versions allowing you to easily move them around your project site. However, there are also permanent substations that you can build with their own components to run on larger sites. Contact us today for the best electrical mining equipment available.

Becker Mining is the industry’s leader in increasingly more sophisticated electrical control systems. Our custom electric mining equipment can transform your specifications into precision products, utilizing state-of-the-art parametric engineering and advanced lean manufacturing techniques.

Contact Us Today

Becker Mining treads the difficult path of managing the needs and expectations of clients while attempting to provide a service to them that is affordable. Our e-house substation series has provided a solution to one of the biggest issues that many miners face: energy demands and how to power their systems for less money. Through careful planning, smart budgeting, and sensible forecasts, Becker Mining's products have helped many mines find ways to save big on substation infrastructure costs. Contact us or visit our website to learn more about how we can help.

Products We Offer:

- Explosion Proof Equipment

- Transformers

- Arc Guard

- Longwall Electrical Systems

- Capacitor Trip Devices

- Electrical Equipments like capacitor banks, switch houses, junction, and splice boxes.

Since 1971, Becker/SMC has been a trailblazer in delivering top-notch electrical components, open-type and explosion-proof motor starters, longwall electrical controls, and power distribution equipment. Our unwavering commitment to quality and customer satisfaction has made us a trusted name in the industry. Contact us today!