Underground mining is one of the most demanding and dangerous industries in the world. Every day, miners work deep below the earth’s surface, surrounded by heavy machinery, powerful electrical systems, and unpredictable environmental conditions. In this setting, safety isn’t just a guideline—it’s a lifeline. One of the critical safety technologies making a real difference is the Arc Guard system, designed to detect and prevent devastating electrical arc flashes before they can harm workers or damage equipment.

At Becker Mining USA, we recognize how important electrical safety is in underground operations. Electrical power is the backbone of mining, but it also comes with risks. High-voltage systems, confined spaces, and moisture-rich environments create the perfect storm for potential arc flash incidents. That’s where the Role of Arc Guard becomes vital—protecting workers, preventing downtime, and ensuring mines can operate with both efficiency and peace of mind.

Understanding Arc Flash Risks in Mining

To fully appreciate the Role of Arc Guard, it’s important to understand what arc flashes are and why they are so dangerous in underground mines.

An arc flash is a sudden release of energy caused by an electrical fault. When electricity strays from its intended path and jumps through the air, it creates an extremely high-temperature arc. Temperatures can soar to more than 35,000°F—hotter than the surface of the sun. The explosive force can cause burns, fire, equipment destruction, and even fatalities.

In underground mines, the risks are magnified because:

- Space is limited – Workers are often in close quarters with energized equipment.

- Moisture and dust – Humidity, groundwater seepage, and conductive dust increase fault risks.

- Continuous operations – Mines rely heavily on electrical systems running 24/7.

- Difficult evacuations – In the event of an incident, escape routes are limited.

This makes preventive solutions like Arc Guard not just beneficial, but essential.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

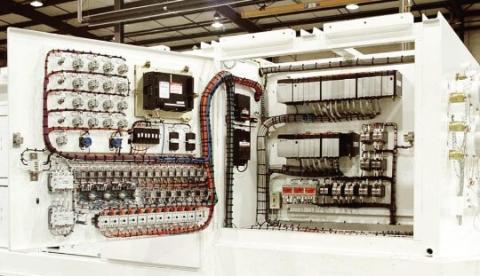

What is an Arc Guard?

An Arc Guard is an intelligent detection and protection system that identifies arc flashes the moment they occur and shuts down the electrical supply before the arc can cause catastrophic damage. Instead of reacting to the destruction afterward, it proactively prevents escalation within milliseconds.

The system typically works by:

- Detection – Using optical sensors, Arc Guard detects the intense light produced during the very first moment of an arc flash.

- Response – It triggers a rapid trip signal to circuit breakers or disconnect switches.

- Containment – By cutting the power almost instantly, it minimizes or eliminates the harmful effects.

The Role of Arc Guard is essentially to be the silent guardian, always watching and ready to act faster than any human response could ever hope to.

The Human Side of Arc Guard Protection

Technology in mining isn’t just about productivity; it’s about people. The Role of Arc Guard is ultimately about saving lives and preserving livelihoods. Imagine a miner working near an electrical cabinet when a fault occurs. Without protection, the results could be fatal. With Arc Guard, the system reacts instantly, cutting power before the worker even realizes there was danger.

Beyond safety, Arc Guard also plays a huge role in:

- Reducing stress for workers – Knowing that protective systems are in place builds confidence underground.

- Supporting mine families – Every miner’s family wants reassurance that their loved one is safe at work. Arc Guard provides that layer of trust.

- Strengthening workplace culture – Companies that prioritize cutting-edge safety solutions show employees they are valued.

Operational Benefits of Arc Guard

Safety is the top priority, but mine operators also recognize the operational benefits that come with Arc Guard systems. The role of arc guard extends beyond life-saving protection to include:

- Minimized Equipment Damage

Arc flashes can completely destroy switchgear, transformers, and cabling. With Arc Guard cutting power immediately, equipment damage is dramatically reduced. - Less Downtime

Every hour a mine is offline costs money. By preventing catastrophic failures, Arc Guard ensures operations resume quickly after incidents. - Lower Insurance Costs

Mines with advanced protective systems are seen as lower risk, helping to reduce insurance premiums. - Regulatory Compliance

Meeting strict electrical safety regulations is easier with proven protective technologies in place. - Long-Term Savings

While installing Arc Guard is an investment, the savings in avoided accidents, equipment replacements, and downtime far outweigh the cost.

Why Becker Mining USA Champions Arc Guard Technology

Becker Mining USA has long been a leader in safety and communication systems for the mining industry. Our commitment is not just to improve productivity but also to ensure that every miner goes home safely at the end of each shift. The role of arc guard fits perfectly into this mission.

By integrating Arc Guard systems into underground operations, Becker provides:

- Cutting-edge reliability – Systems that respond within microseconds.

- Adaptability – Arc Guard can be implemented in both new installations and retrofitted into existing equipment.

- Ease of monitoring – Advanced software tools allow operators to track incidents and optimize safety strategies.

- Peace of mind – A solution miners and operators can trust every day.

Real-World Example: The Power of Prevention

Consider a mining operation running continuous 24/7 shifts. Without Arc Guard, an electrical arc flash in one of the switchgear rooms could destroy equipment, injure workers, and shut down production for days. Costs would skyrocket, and lives would be put at risk.

With Arc Guard installed, the same fault would be detected instantly. Power would be cut within milliseconds, containing the arc before serious damage occurs. Workers remain safe, the equipment is preserved, and the mine continues operating with only minor interruptions.

This is the Role of Arc Guard in action—turning what could be a disaster into a manageable event.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Looking Ahead: The Future of Mine Safety

Mining is evolving, and so is safety technology. As electrical systems become more complex and power demands increase, the risks of arc flash incidents won’t disappear. But with systems like Arc Guard, mines can stay one step ahead.

Future developments may see Arc Guard integrated with smart monitoring platforms, predictive analytics, and even AI-driven safety solutions. At Becker Mining USA, we are committed to being part of this future—where safety and productivity go hand in hand.

Conclusion

The underground mining industry faces unique challenges, but safety must never take a back seat. The role of arc guard in underground mines is clear: it protects lives, preserves equipment, reduces downtime, and provides peace of mind for both miners and operators.

At Becker Mining USA, we believe that technology should always serve people first. Arc Guard is not just a piece of equipment—it is a lifeline for workers who face some of the harshest conditions on earth. By investing in safety today, mines can build a future where every worker has the confidence that they are protected, no matter what challenges lie underground.

Products We Offer:

- Explosion Proof Equipment

- Transformers

- Arc Guard

- Longwall Electrical Systems

- Capacitor Trip Devices

- Electrical Equipments like capacitor banks, switch houses, junctions, and splice boxes.

Power up your productivity with Becker Mining's ground fault relays - the reliable and efficient solution for all your power distribution needs. Call us today!