Mining is more than just digging deep into the earth to extract valuable minerals—it's a complex operation powered by heavy-duty machinery, innovative technology, and the expertise of countless hardworking individuals. Behind every successful mining project is a lineup of powerful, precision-engineered mining equipment that makes the impossible possible. At Becker Mining USA, we understand the critical role that equipment plays in the success and safety of any mining operation.

In this blog post, we’ll break down the most common types of mining equipment used across the industry. Whether you’re new to mining or just curious about how things work underground, here’s a closer look at the gear that keeps the industry moving.

1. Drilling Equipment: The Starting Point

Before any extraction begins, there’s exploration—and that means drilling. Drilling equipment is used to create holes in the earth's surface to collect samples or to establish entryways into underground mines.

Common Types:

- Rotary Drill Rigs – These are used for surface mining operations and can drill through rock to prepare blasting areas.

- Jumbo Drills – These are used in underground mining to drill holes for explosives in hard rock mining.

Why It Matters:

Drilling helps determine the location and quality of ore deposits. It sets the stage for everything that follows. Without accurate drilling, the entire operation could be misdirected—wasting time and money.

2. Blasting Tools: Clearing the Way

Once the drilling is complete and the layout is confirmed, it's time to break the rock using blasting tools. These tools are critical for both surface and underground mining.

Common Tools:

- Explosives like ANFO (Ammonium Nitrate Fuel Oil)

- Detonators and ignition systems

Role in Mining:

Blasting helps loosen rock so it can be removed and transported. This step is crucial in hard rock mining where minerals are deeply embedded in rock formations.

3. Excavators and Loaders: Heavy Lifters

Once blasting is complete, it's time to move the debris. This is where excavators and loaders come in—they’re the muscle behind moving earth and minerals.

Equipment Types:

- Hydraulic Shovels – Ideal for large-scale excavation.

- Backhoe Loaders – Versatile machines used in both surface and underground operations.

- Front-end Loaders – Great for scooping up blasted material and loading it onto haul trucks.

Key Benefit:

These machines save massive amounts of time and manual labor. Without them, mining would be nearly impossible on a commercial scale.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

4. Haul Trucks and Conveyors: Moving Mountains

Transporting minerals and debris from the mining site to processing facilities is no small task. Haul trucks and conveyor systems make it manageable.

Two Major Types:

- Off-Highway Trucks – These enormous trucks carry tons of material at once.

- Conveyor Belts – Frequently used in underground mining to move material more efficiently through narrow shafts and tunnels.

Real-World Insight:

The right hauling system can reduce operation time significantly. At Becker Mining USA, we work with clients to customize transport systems that fit their unique mine layout and material volume.

5. Crushing and Grinding Machinery: Processing the Product

Before minerals can be sold or used, they need to be processed. Crushing and grinding equipment breaks down large rocks into smaller, manageable pieces.

Typical Equipment Includes:

- Jaw Crushers

- Cone Crushers

- Ball Mills and SAG Mills

Why It’s Crucial:

Efficient crushing and grinding improves ore recovery and ensures the valuable materials are separated from the waste.

6. Screening Equipment: Separating the Good from the Bad

After crushing, materials must be sorted. Screening equipment helps miners separate materials based on size, making it easier to identify valuable minerals.

Tools of the Trade:

- Vibrating Screens

- Trommel Screens

- High-Frequency Screens

Becker Mining Tip:

A well-calibrated screening system can increase throughput and reduce processing costs—a win-win for any operation.

7. Underground Support Systems: Safety First

Working underground poses unique challenges. Miners need reliable support systems to ensure tunnels remain stable and safe.

Essential Systems:

- Roof Bolters

- Ground Support Mesh

- Ventilation Systems

Safety Spotlight:

Becker Mining USA specializes in communication and safety systems that integrate seamlessly with underground equipment. Our goal is to ensure every worker returns home safely.

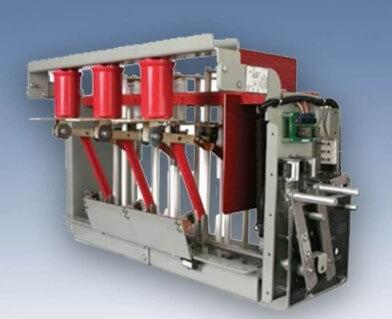

8. Electrical Equipment and Power Supply: Fueling the Operation

Without power, even the most advanced mining equipment is useless. Electrical systems deliver the energy needed to run machines, lights, and safety systems.

Core Components:

- Power Substations

- High-Voltage Cables

- Transformers and Switchgear

Becker Mining Advantage:

Our custom-designed electrical systems are built to handle the harsh environments of mining, ensuring consistent uptime and reliability.

9. Communication Equipment: Staying Connected Underground

Modern mining requires real-time communication between workers, supervisors, and surface control rooms. This is especially critical in underground operations where visibility and accessibility are limited.

Tools for the Job:

- Leaky Feeder Systems

- Two-Way Radios

- Integrated Monitoring Systems

How Becker Helps:

We offer cutting-edge communication systems that keep workers informed, improve response times, and ensure regulatory compliance in even the most remote mining sites.

10. Maintenance and Monitoring Equipment: Keeping It Running

Finally, consistent performance requires regular maintenance. Monitoring systems and diagnostic tools help identify wear and tear before it leads to costly breakdowns.

Key Solutions:

- Condition Monitoring Sensors

- Automated Lubrication Systems

- Diagnostics Software

Final Word:

A good maintenance program, powered by reliable monitoring equipment, extends the lifespan of your investment in mining equipment—saving money and downtime in the long run.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Conclusion: Why It All Matters

Mining equipment isn’t just a collection of steel and hydraulics—it’s the lifeblood of the mining industry. From exploration to transportation, every stage of mining relies on machines that are built to endure, perform, and protect.

At Becker Mining USA, we don’t just provide equipment—we provide solutions. With decades of experience and a commitment to innovation, safety, and reliability, we help our partners get the most out of their mining operations.

Contact Us Today!

Whether you're operating deep underground or on the surface, choosing the right mining equipment is key to success. And when you're ready to take your operations to the next level, Becker Mining USA is here to help you get there—safely and efficiently.

Contact Becker Mining USA today to learn more about our complete line of mining equipment and support solutions tailored to your site’s unique needs.

Products We Offer:

- Explosion Proof Equipment

- Transformers

- Arc Guard

- Longwall Electrical Systems

- Capacitor Trip Devices

- Electrical Equipments like capacitor banks, switch houses, junctions, and splice boxes.

Power up your productivity with Becker Mining's ground fault relays - the reliable and efficient solution for all your power distribution needs. Call us today!