In the realm of electrical engineering, transformers play a pivotal role in the transmission and distribution of electrical energy. Among various types of transformers, dry-type transformers have gained considerable attention due to their safety, reliability, and environmental benefits. Becker Mining USA, a leading provider of mining safety and communications equipment, is at the forefront of leveraging this technology to ensure seamless connectivity in challenging environments.

Understanding Dry-Type Transformers

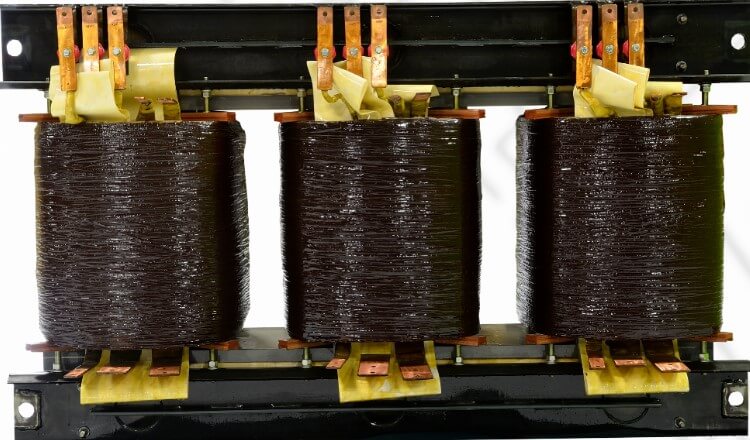

As the name suggests, a dry-type transformer doesn't use any liquid as an insulating or cooling medium for its windings or core. Instead, these components are encased within a sealed tank filled with air or another gas under pressure. This approach offers distinct advantages, especially when operating in harsh conditions such as high humidity, fire risk areas, and seismic events, without compromising performance or posing a hazard to people or property.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Diving Deeper: Types of Dry Type Transformers

Dry-type transformers generally fall into two categories: Cast Resin Dry Type Transformers (CRT) and Vacuum Pressure Impregnated Transformers (VPI).

Cast Resin Dry Type Transformer (CRT): A CRT encapsulates its primary and secondary windings using epoxy resin, protecting them from moisture, dust, corrosion, and other environmental factors. This feature makes CRTs suitable for high-humidity areas, indoor installations, and fire-risk areas. They are non-hygroscopic, non-flammable, and maintenance-free, capable of withstanding overloads, partial discharges, and low losses, resulting in high efficiency and longevity.

Vacuum Pressure Impregnated Transformer (VPI): A VPI uses class H polyester resin to impregnate its windings under vacuum and pressure. This process eliminates air gaps or voids in the insulation, enhancing its mechanical strength, dielectric strength, and thermal stability. VPIs offer robust construction, moisture-resistant enclosure, and low thermal expansion coefficient, making them suitable for outdoor installations, seismic events, and temperature fluctuations.

The Benefits of Dry-Type Transformers

Dry-type transformers provide several notable advantages:

- Safety: They are devoid of flammable or toxic liquids and pose no risks of leaks or fires.

- Maintenance-free: They require no oil changes or oil tests, reducing maintenance costs and environmental impact.

- Easy Installation: These transformers can be installed close to the load, reducing the need for lengthy and costly low-voltage cables.

- Environmental Compatibility: They emit no harmful gases, nor do they contribute to the greenhouse effect.

- Overload Support: They have better heat dissipation and thermal endurance than oil-filled transformers, supporting overloads effectively.

The Limitations of Dry-Type Transformers

Despite their numerous advantages, dry-type transformers also have a few limitations:

- Cost: They are more expensive than oil-filled transformers due to the additional materials and labor required for manufacturing.

- Size: Dry-type transformers are larger and heavier than oil-filled transformers for the same power and voltage rating.

- Sensitivity: They are more vulnerable to dust, dirt, and vermin due to open ventilation.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Applications of Dry-Type Transformers

Dry-type transformers are used extensively across industries prioritizing safety, reliability, and environmental compatibility. For instance, the chemical, oil, and gas industry utilizes dry-type transformers to supply power to various equipment and processes involving flammable or explosive substances.

Advancements in Dry-Type Transformer Technology

In recent years, advancements in dry-type transformer technology have further improved their performance and expanded their applications. These innovations have addressed some of the limitations associated with dry-type transformers, making them even more attractive for various industries and settings.

1. Enhanced Efficiency and Reduced Losses:

One of the key areas of improvement in dry-type transformer technology is enhanced efficiency and reduced losses. Manufacturers have been able to optimize the design and use high-quality materials, resulting in transformers with lower impedance and core losses. This improvement translates to higher energy efficiency and reduced operating costs for end-users. With an increased focus on sustainability and energy conservation, these advancements have made dry-type transformers a preferred choice in environmentally-conscious projects.

2. Compact and Lightweight Designs:

Addressing the size and weight limitations, researchers and engineers have made significant strides in developing more compact and lightweight dry-type transformers. By using advanced insulation materials and innovative core designs, the overall footprint of these transformers has been significantly reduced. This advancement has made them suitable for applications where space is limited or where the installation of large, heavy equipment is not feasible.

3. Enhanced Protection and Monitoring:

Dry-type transformers now come equipped with advanced protection and monitoring systems. These systems can detect abnormal operating conditions, temperature fluctuations, and potential faults. With real-time monitoring and automated safety shutdown features, these transformers can proactively respond to any issues, preventing potential damages and ensuring an un-interrupted power supply. Additionally, remote monitoring capabilities allow operators to access critical data from a distance, enabling efficient maintenance and troubleshooting.

4. Increased Durability and Longevity:

Advancements in materials and manufacturing techniques have led to increased durability and longevity of dry-type transformers. They are now more resilient to environmental factors such as temperature variations, moisture, and vibrations. With improved mechanical strength and better thermal management, modern dry-type transformers can withstand harsh conditions, making them suitable for outdoor installations, marine applications, and remote locations.

5. Customization and Application-Specific Designs:

Manufacturers now offer a wide range of customization options and application-specific designs for dry-type transformers. Clients can choose from various configurations, voltage ratings, and power capacities to meet their specific needs. Whether it's for industrial plants, data centers, renewable energy projects, or critical infrastructure, these customized solutions ensure optimal performance and cost-effectiveness.

6. Smart Grid Integration:

As the power grid evolves into smart grids, dry-type transformers have also adapted to this changing landscape. Smart transformers with digital communication capabilities have emerged, allowing seamless integration with smart grid technologies. These intelligent transformers can communicate with the grid, providing valuable data for load management, demand response, and grid stability. Such advancements contribute to the overall efficiency and reliability of power distribution systems.

7. Environmental Considerations:

Dry-type transformers have always been known for their environmental compatibility, but advancements in technology have further solidified this reputation. The elimination of flammable liquids and the reduction of hazardous materials make dry-type transformers inherently safer and more environmentally friendly than oil-filled alternatives. As environmental regulations continue to evolve, these transformers are likely to remain a preferred choice for eco-conscious projects.

Conclusion

The Future of Dry-Type Transformers

The continuous advancements in dry-type transformer technology have positioned them as a viable and attractive option for a wide range of applications. With their improved efficiency, compact designs, enhanced protection features, and environmental benefits, these transformers have become a go-to solution for industries seeking reliable, safe, and eco-friendly power distribution.

As we look ahead, it is evident that the future of dry-type transformers will continue to be shaped by ongoing research and development. Further improvements in materials, design, and manufacturing processes will likely lead to even more efficient, durable, and versatile transformers. Moreover, the integration of smart grid technologies and the rise of renewable energy sources will create new opportunities for the adoption of dry-type transformers in modern power systems.

At Becker Mining USA, we remain committed to staying at the forefront of these technological advancements. By leveraging the latest innovations in dry-type transformer technology, we strive to deliver superior products that meet the evolving needs of the mining industry and other sectors requiring safe, reliable, and sustainable power solutions. As we embark on this journey of progress, the future looks promising for the widespread adoption and utilization of dry-type transformers worldwide.

Make an Informed Decision

To maximize energy efficiency and cost savings, businesses must evaluate their specific needs and applications when selecting a distribution transformer. Considering factors such as transformer losses, insulation systems, and temperature rise ratings will enable businesses to make informed decisions. For expert guidance in choosing the best transformer for your requirements, reach out to Becker Mining USA today.

Products We Offer:

- Explosion Proof Equipment

- Transformers

- Arc Guard

- Longwall Electrical Systems

- Capacitor Trip Devices

- Electrical Equipments like capacitor banks, switch houses, junctions, and splice boxes.

Since 1971, Becker/SMC has been a trailblazer in delivering top-notch electrical components, open-type and explosion-proof motor starters, longwall electrical controls, and power distribution equipment. Our unwavering commitment to quality and customer satisfaction has made us a trusted name in the industry. Contact us today!

GET IN TOUCH

In a hurry? Call us at 276-285-3841