In the challenging environment of underground mining, safety is more than a priority—it’s a lifeline. At Becker Mining USA, we understand that underground operations demand rigorous standards, especially when it comes to the heart of any mining system: Underground Electrical Equipment.

These systems power lighting, ventilation, communication, and machinery, often under extreme pressure and in highly volatile conditions. With the ever-present risks of electrical faults, gas explosions, water ingress, and mechanical failure, maintaining top-tier safety standards is essential—not only for operational efficiency but for the lives of every miner underground.

In this post, we’ll explore the key safety standards that guide the design, installation, and maintenance of underground electrical equipment. We’ll also look at how Becker Mining USA meets and exceeds these standards to ensure the highest levels of safety and performance.

Why Safety Standards Matter

Mining is among the most hazardous industries in the world. According to the U.S. Mine Safety and Health Administration (MSHA), electrical-related incidents account for a significant portion of underground mining accidents.

Unlike surface operations, underground environments pose unique challenges:

- Limited access and escape routes

- Presence of explosive gases and dust

- High humidity and water exposure

- Constricted working spaces

Without proper electrical safeguards, a minor short circuit can quickly escalate into a life-threatening emergency. This is why underground electrical equipment must adhere to strict engineering and operational standards.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

International and U.S. Standards That Govern Underground Electrical Equipment

To protect both workers and equipment, several governing bodies have created standards for underground electrical systems. Let’s explore the most critical ones.

1. MSHA (Mine Safety and Health Administration)

MSHA sets forth strict guidelines for electrical systems in underground coal and metal/non-metal mines in the United States. These regulations cover:

- Ground fault protection

- Explosion-proof enclosures

- Intrinsically safe circuits

- Cable protection and routing

- Regular inspections and testing

Becker Mining USA designs all underground electrical equipment to comply with or exceed MSHA’s detailed criteria.

2. NEC (National Electrical Code) – Article 500 to 505

The NEC includes articles specific to hazardous (classified) locations, like those found in underground mines. NEC Article 500 deals with explosion prevention in areas where flammable gases or vapors are present.

At Becker Mining USA, our equipment design takes into account classification of hazardous zones and includes:

- Flameproof enclosures

- Sealed cable entries

- Proper grounding systems

3. IECEx and ATEX Standards (for Global Operations)

For international mining sites, IECEx and ATEX standards offer harmonized safety systems for electrical devices in explosive atmospheres.

Becker Mining USA ensures that all exported equipment complies with these international standards, especially in cross-border operations.

Key Safety Features in Underground Electrical Equipment

Let’s explore how these safety standards are applied in real-world equipment. Here are some key features that set safe underground electrical systems apart.

1. Explosion-Proof Enclosures

One of the primary dangers underground is the presence of methane gas and coal dust. If a spark were to ignite these gases, the results could be catastrophic. That’s why explosion-proof enclosures are essential.

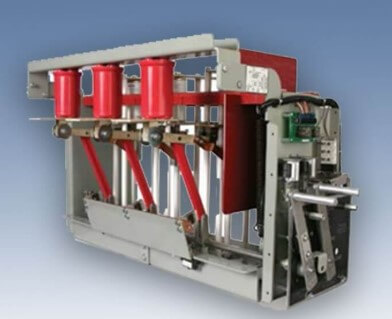

Becker’s motor starters, switchgear, and substations are enclosed in flameproof housings that can contain any internal ignition without letting it spread to the external atmosphere.

2. Ground Fault Protection

Ground faults can be deadly if not detected in time. Modern underground electrical equipment includes ground fault relays that instantly shut down power in the event of a fault, preventing electrocution and equipment damage.

We integrate advanced fault detection systems that continuously monitor resistance and current imbalances across our networks.

3. Intrinsically Safe Designs

For communication systems and sensors in areas prone to gas exposure, intrinsic safety is key. This design philosophy ensures that even if a circuit fails, it won’t produce enough heat or spark to ignite gas.

Becker Mining USA’s communication and control devices follow intrinsic safety design, providing peace of mind in sensitive areas.

4. Water-Resistant and Corrosion-Proof Materials

Mines are often wet, humid, and chemically reactive environments. Electrical equipment must withstand prolonged exposure without degrading.

We use stainless steel enclosures, waterproof connectors, and anti-corrosion coatings to enhance the durability of our underground electrical equipment.

5. Remote Monitoring and Automation

Human error is a leading cause of electrical incidents. By integrating remote monitoring and automation into our systems, Becker reduces the need for manual intervention.

Our smart systems can detect potential issues—like overheating, overloads, or abnormal voltages—and trigger alarms or automatic shutdowns to prevent failure.

The Role of Training and Maintenance

While design and manufacturing are critical, even the best underground electrical equipment can fail without proper handling. That’s why training and routine maintenance are an integral part of mine safety.

Becker Mining USA partners with operators to:

- Conduct on-site training for electricians and engineers

- Provide digital manuals and maintenance schedules

- Offer emergency support and remote diagnostics

We also offer equipment audits to identify potential hazards before they become dangerous.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

A Culture of Safety at Becker Mining USA

Our mission goes beyond manufacturing equipment—we aim to cultivate a safety-first mindset across the entire mining sector. At Becker Mining USA, safety is embedded in every layer of our process:

- Design & Engineering: Every product undergoes risk assessments and compliance checks.

- Manufacturing: We test all components under simulated underground conditions.

- Deployment: We supervise installations to ensure everything runs to spec.

- Support: Our team provides ongoing guidance for equipment use and upgrades.

Our innovation in underground electrical equipment doesn’t just power operations—it protects people.

Looking Ahead: Future-Proofing Underground Electrical Systems

As the mining industry evolves with automation, electrification, and digital integration, so too must our safety standards. Becker Mining USA is already pioneering the next generation of underground safety solutions, including:

- Battery-powered mobile substations

- AI-based fault prediction tools

- Integrated communication-electrical hubs

- Low-emission electrical ventilation systems

The future of mining will be safer, smarter, and more sustainable—and Becker is proud to lead the way.

Conclusion

The underground mining environment demands respect. It's an arena where a single lapse in electrical safety can have devastating consequences. That’s why at Becker Mining USA, we don’t compromise when it comes to the design, deployment, and maintenance of underground electrical equipment.

Through strict compliance with MSHA, NEC, and international standards, combined with advanced design features and ongoing support, we help mining operations stay safe, efficient, and forward-thinking.

When lives are on the line, only the best will do—and Becker Mining USA is committed to delivering just that.

Looking To Upgrade Your Underground Electrical Systems?

Connect with our safety engineers today and discover how Becker Mining USA can help safeguard your operations from the ground up.

Products We Offer:

- Explosion Proof Equipment

- Transformers

- Arc Guard

- Longwall Electrical Systems

- Capacitor Trip Devices

- Electrical Equipments like capacitor banks, switch houses, junctions, and splice boxes.

Power up your productivity with Becker Mining's ground fault relays - the reliable and efficient solution for all your power distribution needs. Call us today!

GET IN TOUCH

In a hurry? Call us at 276-285-3841