Explosions pose a significant risk in various industrial settings, including petrochemical refineries, cleaning facilities, flour silos, and landfill sites. These explosions occur when flammable substances combine with oxygen and an ignition source. To minimize this risk, implementing explosion-proofing measures is crucial, particularly regarding electrical equipment.

Understanding Explosion-Proofing

Explosion-proofing involves limiting access to air, controlling potential ignition sources, and containing explosions within suitable enclosures. Classifying the hazardous environment is vital to determine the explosion-proofing level required.

Classification Systems

In North America, hazardous areas are classified as Class I (flammable vapors or gases), Class II (flammable dust), or Class III (ignitable fibers or flyings). These classes are further divided into Divisions and Groups, specifying the likelihood and specific substances that can cause an explosion. Equipment surfaces are assigned temperature ratings from T1 to T6, indicating the maximum allowable temperature.

Europe uses the Zone system, which categorizes hazard probability into three levels. Zone 0 represents a continuous explosive atmosphere, Zone 1 indicates an intermittent or periodic explosive atmosphere, and Zone 2 refers to an explosive atmosphere under abnormal conditions. Zones are also subdivided into Groups based on the type of flammable substance present.

The Role of Connectors

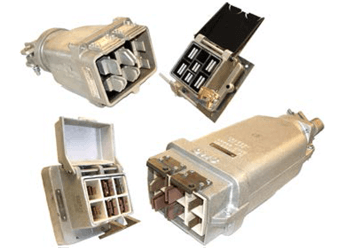

Connectors play a crucial role in explosion-proofing, as they can generate arcs and sparks during regular operation. Manufacturers of explosion-proof connectors employ various methods to minimize or contain arcs within specialized receptacles. According to relevant standards, these connectors are designated as safe for specific hazardous environments.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Becker Mining USA's Solutions

Becker Mining USA offers a range of explosion-proof connectors designed for hazardous locations. The Ultra Lock connection system is engineered for Class I, Division 2, and Zone 2 environments. These circular connectors feature a built-in locking mechanism, ensuring secure mating that requires a screwdriver for unmating. With non-arcing connection points, they are suitable for areas where flammable gases or vapors may occur during abnormal conditions, including food and beverage processing, oil refineries, and pharmaceutical manufacturing.

For applications in natural gas processing equipment, mining, and offshore platforms, Becker Mining USA provides explosion-proof industrial connectors. These connectors are manufactured with precise tolerances in mating junctions, minimizing contact exposure to an explosive atmosphere. They are certified for Zone 1-IIC applications and offer T5 and T6 ratings.

Product Features and Variations

Becker Mining USA offers a variety of backshell arrangements and contact inserts for power (up to 1135A at 1000V), signal (up to 143 contacts), and hybrid power control applications. The connectors support copper, fiber optics, coaxial, or mixed conductors and are available in RJ45 and USB versions. Their compact design ensures compatibility with smaller wire gauges, providing versatile power and signal connectivity solutions.

Choose Safety with Becker Mining USA

Companies can enhance safety in hazardous industrial environments by specifying explosion-proof cable connectors. Becker Mining USA understands the classification systems and offers expert guidance in selecting the ideal components to protect electrical systems. Count on us to mitigate the risk of explosions caused by electrical equipment and prioritize safety in your operations. Call our experts today!

Products We Offer:

- Explosion Proof Equipment

- Transformers

- Arc Guard

- Longwall Electrical Systems

- Capacitor Trip Devices

- Electrical Equipments like capacitor banks, switch houses, junctions, and splice boxes.

Since 1971, Becker/SMC has been a trailblazer in delivering top-notch electrical components, open-type and explosion-proof motor starters, longwall electrical controls, and power distribution equipment. Our unwavering commitment to quality and customer satisfaction has made us a trusted name in the industry. Contact us today!

GET IN TOUCH

In a hurry? Call us at 276-285-3841